The Australian beer market continues to mature, with craft and large-scale breweries alike facing increasing pressure to deliver consistent flavour, clarity, and shelf stability. As competition intensifies and regulatory expectations rise, filtration has become a critical control point in beer production. Selecting the right beer filter in Australia is no longer just about clarity—it directly impacts taste, process efficiency, and overall production economics.

CoPure supplies Cobetter beer filtration solutions engineered specifically for brewery applications, supporting Australian brewers with reliable, scalable, and technically proven filtration technologies.

Beer is produced from four primary ingredients—malt, water, hops, and yeast—each contributing to flavour, aroma, and alcohol content. During brewing and fermentation, suspended solids such as yeast cells, proteins, hop residues, and colloidal particles must be carefully managed. Inadequate filtration can lead to:

Modern beer filtration balances effective particle removal with minimal impact on sensory characteristics. This requires filtration media that provide high dirt-holding capacity, predictable flow rates, and long service life.

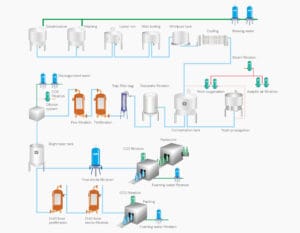

Cobetter provides professional-grade filtration systems designed for the full beer production process, including:

By optimising each filtration step, breweries can reduce process losses, improve throughput, and maintain consistent product quality.

At the core of Cobetter’s beer filtration offering is the CSD Filter Series, a depth filtration solution widely used in beverage processing.

CSD filters are constructed from high-quality lignocellulose combined with inorganic filter aids. The proprietary 3D crisscrossing internal structure enables true depth filtration, capturing particles throughout the filter matrix rather than only on the surface.

This design delivers:

Unlike traditional surface filters, depth filters reduce premature clogging and minimise pressure build-up, making them well-suited for beer clarification and pre-filtration stages.

Cobetter CSD beer filters offer several performance advantages important to Australian breweries:

These characteristics allow brewers to achieve consistent clarity while maintaining high flow rates and predictable operating conditions.

These parameters make CSD filters suitable for demanding brewery environments where thermal stability and cleaning compatibility are essential.

Cobetter CSD filters are available in multiple lens configurations, allowing breweries to scale filtration capacity according to batch size and production volume.

| Number of Lenses | Filtration Area (Ø12″) | Filtration Area (Ø16″) |

| 9 | 0.9 m² | 2.1 m² |

| 12 | 1.1 m² | 2.8 m² |

| 15 | 1.4 m² | 3.5 m² |

| 16 | 1.5 m² | 3.7 m² |

This modular design supports both small craft breweries and larger commercial operations without requiring major system redesigns.

Depth filtration effectively removes yeast and haze-forming particles, delivering bright beer without aggressive processing.

Pre-filtration using CSD filters protects downstream membrane or final filters, extending their service life and reducing replacement costs.

Consistent particle and colloid removal improves physical stability, reducing the risk of haze development during storage and distribution.

Australian breweries partner with CoPure for more than just supply:

For breweries seeking a dependable beer filter Australia, CoPure combines Cobetter’s proven filtration technology with local expertise to help maintain product quality while improving operational efficiency.

By integrating beer filtration solutions into your brewing process, you gain better control over clarity, stability, and cost—key factors for long-term success in Australia’s competitive beer market.

For Further Enquiry Contact- sales@copure.com.au