In laboratories and manufacturing facilities across Australia, membrane filtration plays a crucial role in ensuring product purity, analytical accuracy, and process reliability. As industries demand higher precision and regulatory compliance, choosing the right membrane filter is no longer just an operational decision—it directly impacts quality, consistency, and cost-efficiency.

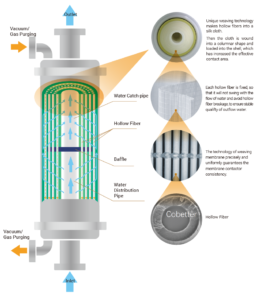

CoPure supplies one of the most advanced and diverse membrane filtration portfolios in the country, powered by Cobetter, a global leader known for high-performance filtration technologies. Whether you need membranes for sterile filtration, sample clarification, microbial retention, or gas/air filtration, CoPure ensures Australian labs and production units have access to reliable solutions backed by fast delivery and technical support.

Cobetter’s membrane technologies are used in over 80+ countries and adopted by pharmaceutical manufacturers, biotech labs, beverage producers, and industrial facilities worldwide. Their membranes undergo rigorous testing for flow rate, retention efficiency, pressure resistance, thermal stability, and extractable levels—ensuring predictable performance across fluids and operating conditions.

CoPure makes these globally trusted filters readily accessible in Australia, supporting everything from research laboratories to large bioprocessing plants.

Different applications demand different membrane chemistries. Cobetter’s portfolio—readily supplied by CoPure—includes:

This material diversity ensures that Australian labs can choose the membrane that aligns with their process conditions, sample type, and regulatory standards.

Cobetter membranes are engineered with highly uniform pore structures and are available in pore sizes ranging from:

This precision ensures absolute retention, not nominal retention, which is essential for critical applications in biotechnology, pharmaceuticals, and food production.

A major cost factor in filtration systems is the pressure required to maintain throughput.

Cobetter membranes are optimised for:

This means lower operational costs, fewer filter replacements, and greater process continuity—especially important in high-volume industries like beverage production or pharmaceutical media preparation.

CoPure offers:

Sterile filters undergo integrity testing and are supported by validation documents—including bacterial retention, extractables, and compatibility reports—available on request.

The pharmaceutical sector in Australia is rapidly expanding, with a projected CAGR of 4.3% through 2030, increasing demand for compliant filtration systems.

Cobetter’s low-extractable and ultra-pure materials ensure no interference with downstream analysis—a key requirement for diagnostics and QC labs.

Australia’s beverage sector is increasingly adopting membrane filtration due to its non-thermal, preservative-free approach to ensuring product quality.

Membrane filters allow laboratories to achieve consistent results that meet Australian regulatory standards.

CoPure offers guidance on:

This consultative approach helps businesses reduce trial-and-error costs.

With Melbourne-based inventory and fast logistics partners, CoPure ensures a consistent supply critical for industries working under tight production timelines.

From university labs to large-scale pharmaceutical manufacturers, CoPure supports:

In an environment where accuracy, compliance, and efficiency define success, choosing high-quality membrane filtration solutions is essential. CoPure brings world-class Cobetter membrane technologies to Australia — backed by strong technical support, diverse material options, and proven performance across industries.

For laboratories and manufacturers looking to upgrade their filtration performance, CoPure provides membrane filters Australia customers rely on for reliability, consistency, and value.

For Further Enquiry Contact- sales@copure.com.au